Hot Tub Cover LA Spas Fiji 83 Square Light Grey Marine Grade Vinyl

Why We Are The Best! The Worlds Finest Spa Cover. This is the worlds best hot tub cover, it is classified for ASTM Safety, it is supplied with our industry leading specification including 5-3 inch triple "thickness" vapour barrier tapered cores a continuous heat seal and CAD cut vinyl and matching inserts for an exacting fit that makes it the worlds greatest spa cover. Our covers have been independently tested and pass all ASTM standards for weight load requirements........ Colour: Light Grey Lid Type - Square with radius corners Square lid - 83 inches Radius: 10 inch Strap Position: C Length: 14" Adjustable Skirt: 6 inch (split) Core Density: High grade virgin EPS150 Lid/Core Taper: 5-3 inch Core Wrap: Triple "thickness vapour barrier Continuous Heat seal: Full.

Every spa lid has the same fundamental components, the only difference is the quality of materials and the production processes employed to manufacture and construct the lid. So this is the way to easily show you the difference between us and the competition. We stock covers made by the worlds market leader so please take the time to compare us to the competition and you will see why we lead the market. The easiest way is to break down the lid into its component parts to show you the quality of our product. Unique in Europe our vinyls are the manufactured using CAD driven cutting machinery, the obvious benefit is very consistent quality and precision craftmanship.

The vinyl exceeds ASTM Safety Standards and are all tested by an independent laboratory, all our stock covers irrespective of options are classified for ASTM Safety, other companies have done the same but they have gone a step further and are UL registered. Please note the colours shown are representations of the vinyl and may vary. Why our Marine Grade Vinyl is the best. Increased resistance to chlorine and bromine. Cold cracking freeze resistant to -30 degrees Celsius. Oil & Sulfide Stain resistant. Resistant to Salt Water staining. Easily cleaned with soap and water. All these features provide longevity and all year round beauty. The vinyl has the flexibility to stretch with the core rather than failing at points of stress, typical of cheaper alternatives. This allows with the exacting cut of computer aided cutting the cores to be tight fitting providing exact fitment resulting in minimal chances of duck ponding at the hinge (our most common failure).Marine Grade Vinyl was developed for the harsh climates experienced in the boating industry. To be classified as a marine grade, the vinyl has to meet certain requirements, ours meet and surpass these requirements. With a high weight grade per lineal yard, the vinyl used in all our stock covers is the heaviest available. It exceeds the specifications of "Marine Grade Vinyl", and "Premium Grade Vinyl".

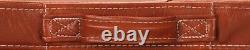

All our covers are completely double stitched together (main stress points more) with the highest quality thread. The vinyl in these stock covers have increased resistance to chlorine and bromine, whilst the backing fabric, is reinforced 100% polyester mesh.Unlike cotton backing, it will not rot, is mildew resistant and adds exceptional strength. We reinforce the handles and tend not to use inferior black mesh handles, we fully integrated them into the lid and use five layers of internal reinforcement. This adds strength where it is most needed. Additional stitching and internal reinforcement make them one of the strongest handles available on the market.

Unlike the majority of handles on many covers (which tend to be a great weak point), these spa cover handles have been designed and engineered to be one of the strongest! As most customers can testify handles are fantastic when the cover is new, but over a long period of time most covers eventually get a bit heavier. Cover handles, having such a small attachment area can be easily torn off, sometimes tearing the cover. Our cover's handles are made of extremely strong, 1-1/2 wide nylon webbing.

As standard we additionally have the nylon handles vinyl covered for extra support but also for better aesthetics. Due to our extensive knowledge and to cut down the cost of heating your tub we provide a complete heat seal on all our covers irrespective of price - all other lid manufacturers charge you for this optional add on. Our insulating heat seal sits where the two halves fold together. Most competitors covers have "fingers".These are two pads laced on the underside at the ends of the cover, between the two halves to prevent steam and heat from escaping when the cover is installed on your spa. If you turn one of these covers upside-down you'll actually see that they also push the two insulating halves apart, leaving as large as a one inch gap between the two halves.

This is equal to having a hole the size of a football in your cover, pointless!! This is why free of charge we install a complete heat seal. Each cover comes standard with four tie-downs equipped with locking child resistant safety latches.To insure the integrity and prevent the straps from ripping out (perhaps from extreme winds), the straps are sewn into the cover, you can view the positions in our dimensional drawings on the individual stock covers. This makes them virtually tear-proof if fitted correctly. Please note it is always advisable in extreme weather conditions to use storm straps for additional support. The clips are key lockable for that added bit of security (male and female parts and fitting screws are all supplied).

The straps keep out unwanted visitors and are quickly installed with two stainless steel screws (provided). They are side pinch release which is easier to use and wear better in colder climates. Our skirt is double stitched into the cover for strength and to provide the best protection. This keeps the precious heat in and unwanted dirt out. We only use zippers designed to maintain their "zipping" ability for years. Besides having large teeth, they're rust and chemical corrosion proof. They are also quadruple stitched for added strength and durability.We use bonded, UV resistant Dacron Polyester thread. The polyester part is important, unlike cotton thread (or cotton wound polyester) it won't rot in a short period of time, and the UV resistance prevents any degradation from the sun.

"Bonded" means that it's actually water tight and can't absorb mildew causing moisture. The zips are imperative if anyone ever steps on your cover or your cores bow, as you can then remove them and turn them over. Simply put, our custom covers use the highest grade virgin insulation available in Europe, this thicker grade and higher density insulating core will easily meet your hot tubbing needs. Our cores are made using CAD (Computer aided design) meaning an exacting fit with superior quality.No other European company offers this quality of craftmanship - this gives a tighter fit reducing the duck pond effect at the centre hinge. Our 5-3 tapers allow the rain water to naturally drain off, inferior spa lids are flat or offer little or no taper and will quickly form puddles on the lid surface eventually breaking down the polystyrene insert cores. Our taper offers the best combination of strength and heat retention whilst keeping the weight of the cover manageable for lifting and operating. Be aware greater depths of covers do not necessarily mean better insulating or strength characteristics, as when talking about insulation, density is preferable to thickness, an example of this is loft insulation, 10 years ago we all insulated using 8" rolls, now with product development we can provide better insulating properties with 2" rolls, it is the same for hot tub lid inserts - thicker is rarely better than denser. Therefore thickness by itself is not a guarantee of better thermal qualities or indeed strength - you need to be aware of all factors to make a comparison.

But in our case extra thickness when combined with extra density does make a big difference - the ideal combination for our energy saving cover. The aluminium steel (rust proof) insert.

We use a rust proof aluminium steel insert strip that sits precisely in the core down each fold. This provides greater reinforcement across the centre of the hot tub cover preventing sagging & the resulting heat loss. Other companies typically use stud wall components or even plumbing pipe to allow them to compete on price as steel by its nature is more costly to fabricate, we fabricate our own channels and are far superior removing the potential for distortion, sagging, heat loss and breakage.

95% of lid failure is due to water ingression, spa covers do eventually get waterlogged and become too heavy to use, we take every opportunity to increase the cover's defense and push that water saturation date back. We use a specially formulated 6 mil (USA terminology) plastic barrier developed to inhibit moisture absorption. This Triple "thickness" Vapour Barrier is as standard for extra protection (most companies single wrap). We then impulse heat seal it together to provide greater strength and durability.

Most of our competition use off the shelf 1 mil polythene and gaffa tape it together. We use state-of-the-art equipment to heat seal the cores. No other company in Europe that we know of does this, the reason being the cost of machinery and time taken to carry out the seal. Unlike the less-expensive methods of sealing, all human variables are eliminated, so your cover gets a perfect seal every time. FACT: All Expanded PolyStyrene (EPS) cores become saturated with water when used in a spa cover application.

The vapor barrier film is only as good as its sealing technology. We have a hard time believing that some cover manufacturers still tape their sheathing shut, but they do. Here is a breakdown of the technologies employed. Taping: Unless done with the proper tape and professional done, this is a step above nothing.Heat Shrinking: In years gone by this was the premium way of sealing cores. Not particulary good because during the shrinking process the sheathing becomes very porous. Heat-shrunk foam cores (Normally Chinese covers) have been reported to absorb water to their maximum level in as little as 12 months. Pneumatic, Impulse Band Heat Seal: We use this preferred method of seal technology our sealer produces a molecular level seal which out performs the inconsistent results of hand-sealers. Combined with our 6 mil vapor barrier, our spa covers can out perform the competition in fighting water absorption in the foam core.

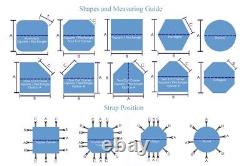

Measuring Your Lid / Spa. If you want a more comprehensive measuring guide - or a print off then we have produced a measuring guide.Which will guide you through easily measuring for your new hot tub lid. If your current cover fits perfectly, then measure the cover, there is nothing better.

However, if your cover is waterlogged, warped, or misshapen, you should measure your spa as well to ensure the new lid fits properly. Should I pick a larger cover?

Many sites offer this, but we distribute and stock covers so we think a good fit is better, not necessarily for functionality but for aesthetics. An overhang of 0.75 per side is negligible in our experience, anything larger, we would not recommend, obviously never order a smaller cover? Never measure the exact hinge as it is typically 1shorter than the actual lid. If your spa has radius corners, then to correctly measure the corner radius use a carpenter's square or use our radius template downloadable at our website.

The key is not to make the radius too big, when in doubt take the smaller measurement. Have a look at the movie in the photo gallery to see how to measure up for a new lid.

The skirt protects the acrylic of your spa from UV damage, so it's important that the skirt covers the acrylic. If your spa has a rail that sticks out from the cabinet under the acrylic, most people extend the skirt down past the rail.

If you do this, be sure the cover is wide enough around so that the skirt can hang straight down. Please measure cover safety straps from the bottom of the cover down to where the strap meets the clip (don't include the clip itself). We provide both parts of the strap fixings but more often than not resiting them slightly gives greater strength rather than using the existing screw holes. Please see the photo gallery for the strap position diagram.

If you need assistance deciding if this is the correct cover for you please drop us a message and we will be happy to help. This item is in the category "Garden & Patio\Swimming Pools, Saunas & Hot Tubs\Hot Tub Covers". The seller is "yampydad" and is located in this country: GB. This item can be shipped to United Kingdom.

- Item Thickness: 3-5 in tapered

- Shape: Square

- Item Diameter: 83 in

- Grommet Material: Vinyl

- MPN: 45145

- Material: Vinyl

- Item Length: 83 in

- Suitable For: Hot Tubs

- Brand: H.T

- Type: Hot Tub Cover

- Unit Type: kg

- Item Height: 6 in (15.2 cm)

- Country/Region of Manufacture: Canada

- Unit Quantity: 40